We design impactful physical and digital products.

Your product, your vision – crafted to stand out and succeed.

Product Design

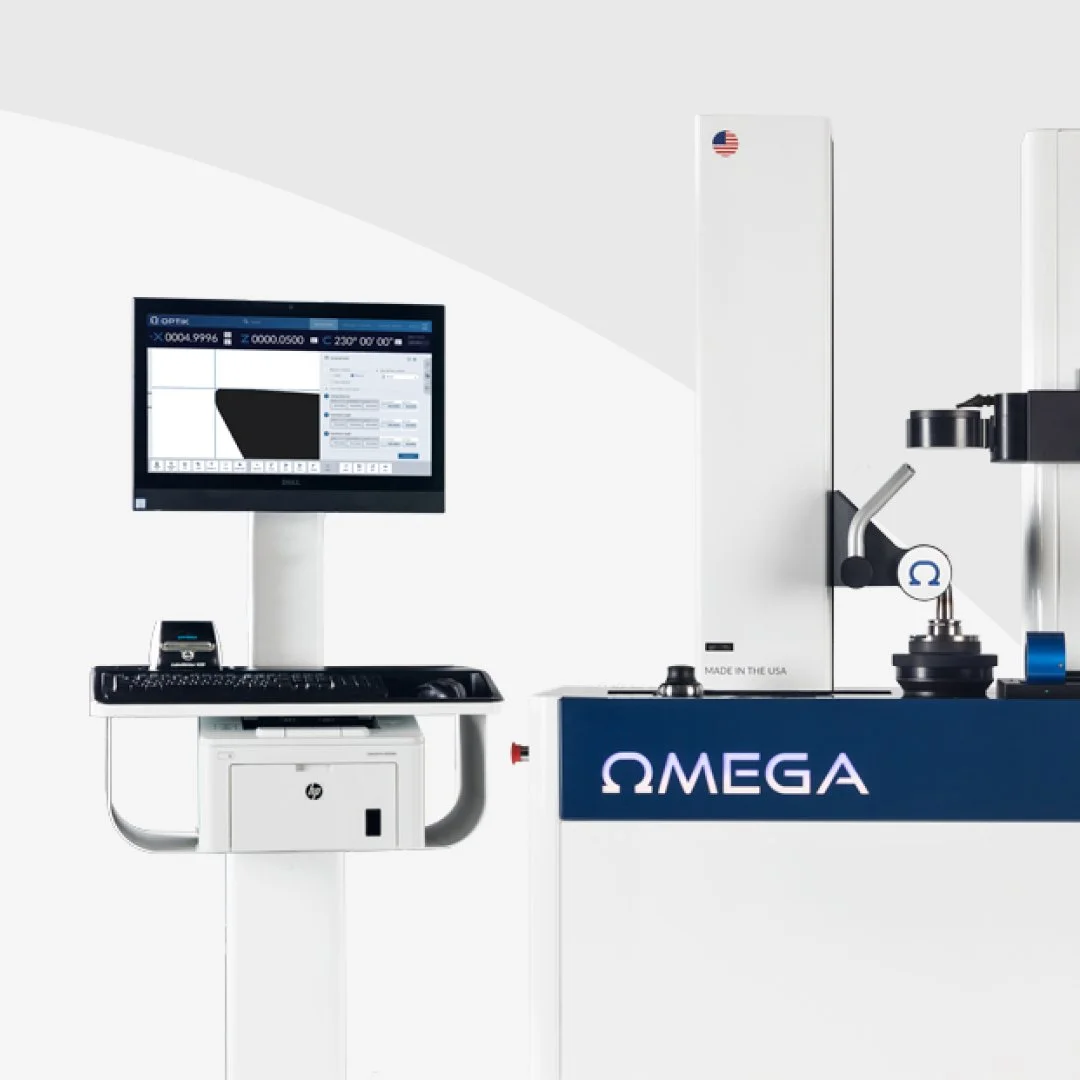

Providing industrial design and engineering to bring physical products to life through thoughtful, user focused design.

Brand Development

Crafting powerful brand identities that resonate with your audience and align with your business goals.

Digital Experiences

Creating engaging user interface and website solutions that enhance user experience and drive engagement.

Marketing Support

Developing cohesive graphic design materials and marketing solutions to effectively reach your goals.

Our Work

We are experts at bringing ideas to life.

Our passion lies in blending user-centric design with a deep understanding of branding principles, creating captivating solutions that are fully aligned with your brand. Whether your needs begin with a logo, a marketing campaign, or a product of any scale, we've got you covered with our multidisciplinary approach.

Hear from our clients about the impact of our work.

Let’s create something amazing together.

Have an idea? Looking for innovative solutions? We’re ready to help you achieve your goals with a custom design solution.